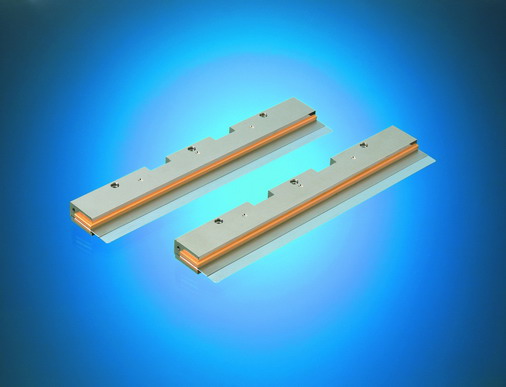

METAL BLADES & HOLDERS Achieve or exceed Original Equipment Manufacturer's (OEM) specifications with JNJ's drop-in replacement

metal squeegee blades and holders. Our OEM line includes flat metal blades, adjustable angle metal

blades, combination plastic and metal blades and squeegee blade holders for leading manufacturers such

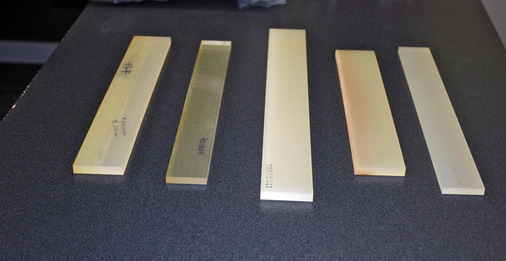

as MPM/Speedline, Fuji, DEK, deHaart, Panasonic, EKRA, Juki and SMTech.  ELECTROLIZE COATING JNJ's metal blades are a stainless steel base metal with our exceptional Electrolized coating. The coatingconsists of a proprietary blend of chromium and other elements, making available a hard

surface of Rc 70/72 Rockwell. Electrolizing offers consistent and reliable performance for today's SMT printing needs and future applications. The Electrolized surface treatment is a technology that

addresses an engineer's five most critical needs: Hardness • Adhesion • Lubricity • Conductivity • Precision The combination of these five design-in features provide an unsurpassed, consistent, reliable technology for applying solder paste, conductiveand nonconductive adhesives to stencils for the

printed circuit board industry.

Why JNJ Metal Blades... ▫ Custom lengths up to 30"

▫ Electrolizing Rc 70/72 Surface Hardness

▫ Absolutely Will NOT Chip, Flake or Peel

▫ Remarkable Wear Resistance

▫ Superior Corrosion Protection

▫ Extraordinarily Low Coefficient of Friction

▫ Delivers Crisp Print Deposits Time After Time

▫ Smooth Sliding Properties

▫ Electrolizing is Conductive

▫ Eliminates Electrostatic Buildup & Discharge

▫ Masking & Outgassing are Not an Issue

▫ Satin Gray Appearance

▫ Precision & Uniformed Plating

▫ Absolute Adhesion - Entire Surface is Coated

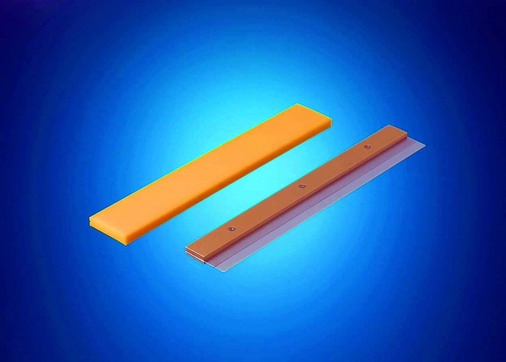

▫ Stain Resistant POLYURETHANE SQUEEGEE BLADES JNJ's POLYURETHANE SQUEEGEE BLADES are machined, not molded, from cast sheets of high quality

polyurethane and high density polymer (HDP). Machined blades not only offer increased operational performance but are available in durometers ranging from 50 through 120 and 180. Precision machined blades resist solvents, have sharper edges, and maintain tighter tolerances than molded blades and can be machined to your specifications to fit any printer ever made. Check out our hand-held holders with blades for manual printing.  HARDER POLYURETHANE BLENDS JNJ has turned to harder polyurethane blends to provide better performance for fine and ultra-fine pitch printing of solder paste and other high viscosity materials. Our machine-sharpened edges provide uniform deposition without scavenging. The advantages of using harder polyurethane blades versus noncoated metal blades include: lower cost, no etooling, and little or no stencil wear or damage. In Stock: - Panasonic SP60 Blade (Length: 350mm); - Samsung SP-400 Blade (Length: 350mm); - Panasonic SPPV Blade (Length: 300mm); |